The case for the automation in single particle analysis software

More and more life scientists are adopting cryo-electron microscopy (cryo-EM) to advance their research and pharmaceutical projects. Yet, as the technique grows in popularity, so too does the strain on time and resourcing for expert users and their teams.

Data collection for cryo-EM is still a very manual, complex process—one that requires a high level of operator time and expertise. If we look at the adoption of cryo-EM in the pharmaceutical industry for instance, we see that the workflow’s complexity has placed new pressures on drug discovery teams. The effort it takes to increase experience and capacity at pharmaceutical companies is likely limiting throughput and impacting their ability to keep up with the pace of medicinal chemistry and protein engineering.

Across pharmaceuticals, biotech and academia, there is a clear need for the incorporation of automation, especially in single particle analysis software for faster, more efficient and better-quality cryo-EM results accessible to expert and non-expert users.

New Thermo Scientific Smart EPU Software

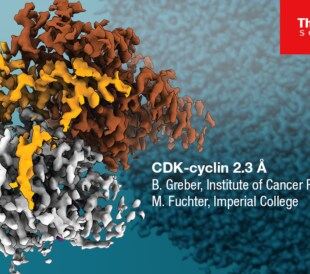

Made possible through forward-looking insights, feedback and close collaboration with structural biologists around the world, we introduce our new Thermo Scientific Smart EPU Software—a single particle analysis software solution that offers more automation capabilities for cryo-EM data acquisition than ever before.

This new software ecosystem is designed to reduce the number of manual steps it takes to set up and run a cryo-EM experiment, ensure data collected is of the highest quality possible, and provide on-the-fly, AI-assisted data analysis and decision-making.

Smart EPU Software is now available across Thermo Fisher Scientific’s cryo-TEM portfolio, including on the Thermo Scientific Tundra, Glacios, and Krios Cryo-TEMs. For any of the three microscopes, Smart EPU can be customized to meet a lab’s needs. Configuration options include the next-generation Thermo Scientific EPU 3 for semi-automated data acquisition, Thermo Scientific EPU Quality Monitor (EQM) for on-the-fly evaluation of image quality during acquisition, and EPU Multigrid for increasing efficiency by enabling unattended data collection.

Some particularly exciting Smart EPU features enable users—new and experienced—to immediately identify problematic acquisitions and fix or skip them for better microscope efficiency and higher throughput capacity. These include the EPU 3 Traffic Light for easy visualization of the microscope’s status and automated corrections to ensure optimal microscope state; a user-guided and automated microscope setup process, including AI-assisted target/grid hole selection for ease-of-use and to reduce time-to-data; smart plugins for automatic adjustments based on real-time data without the need for user decisions based on processing results; automatic microscope behavior correction to remove the need for constant hands-on operation during data acquisition; and an open Application Programming Interface (API) platform, allowing the community to develop and add their own algorithms to the Smart EPU ecosystem.

In combination, the Smart EPU single particle analysis software platform enables automated setup, faster data acquisition capabilities than existing packages, real-time quality assessments and AI-assisted decision-making.

Streamlining cryo-EM software to advance structural biology efforts worldwide

Just as life scientists are pushing the bounds of drug discovery, we aim to do the same when it comes to technological innovation.

By adding automation capabilities to our entire cryo-TEM portfolio, we’re putting the most efficient and highest quality solutions in the hands of those making the world healthier, cleaner and safer.

We hope that the addition of the Smart EPU single particle analysis software platform to our cryo-EM solutions suite will change the way life scientists collect data on cryo-electron microscopes, making acquisition easier than ever, reducing the time required to earn quality results and improving throughput, reliability and repeatability of cryo-EM pursuits.

Learn more about Thermo Scientific Smart EPU Software >>

//

Edward Pryor is Director of Product Development for Life Sciences at Thermo Fisher Scientific

Leave a Reply