Editor’s Note*: We received an inquiry from a a reader related to this article. Read the end of the article to see the question and our expert’s answer.

We have previously looked at “product effect” as one of the biggest food safety and quality challenges in the food industry, especially for baked goods, meats, and dairy products. Product effect becomes a challenge when a product has a conductive property which affects the magnetic field generated by a food metal detector. This effect is typically found in high salt, high moisture products and can affect the ability of the food inspection equipment to accurately ‘find’ metal contamination.

Orientation is a second challenge for many food metal detectors on the market today. It is not uncommon for pieces of metal, especially wires from filters and strainers to break off and contaminate packaged food products. Several years ago, there was a voluntary food recall for cottage cheese due to the potential presence of pieces of metal that may have been introduced during production. The company worried that consumption of a sharp foreign material could cause injury to teeth, mouth, throat, stomach or intestine tissues if swallowed. Another voluntary recall involved infant formula because of the potential presence of metal foreign matter in a single lot of the product.

If food production companies utilize food metal detectors in their plants, they may think they have no reason to worry. However, they should be concerned that there is a possibility that their food metal detectors are not catching all foreign metal objects.

Food grade metal detectors find small particles of ferrous, non-ferrous and stainless steel using coils wound on a nonmetallic frame and connected to a high-frequency radio transmitter. When a particle of metal passes through the aperture, the electromagnetic field is disturbed under one coil, changing the output signal by a few microvolts. The output is used as an indicator that metal is present.

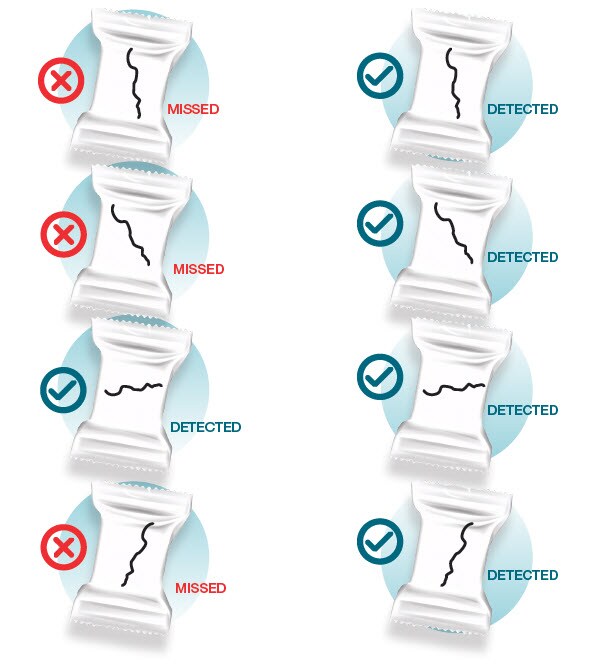

With some metal detector technology, an oblong contaminant must have a specific orientation to be detected when passing through the metal detector. Depending on how the metal detector is configured, horizontal, vertical, or diagonal contaminant orientation could go undetected. And in a fast-running food plant, there’s no predicting how a piece of wire or shaving will land in a product.

Fortunately, there is technology that can alleviate this concern. A food metal detector that utilizes Multiscan technology can inspect product with up to five frequencies at once. A Multiscan metal detector enables users to detect not only smaller contaminants, but contaminants in the most challenging orientations. It is like having five metal detectors in one, which gives food processors the highest probability of finding ferrous, non-ferrous, and stainless steel metal contaminants. (See poster.)

As previously mentioned, in addition to being able to detect metal at different orientations, Multiscan metal detectors also help mitigate product effect. Most metal detectors employ a limited number of frequencies (e.g., one or two simultaneously) to protect product from metal contamination. The goal has been to pick the best frequency to optimize detection. Unfortunately, this is a compromise because there is no single ideal frequency to detect any contaminant inside the product. The result is that sensitivity is impacted, leading to “escapes.”

The best way to overcome the challenge of product effect is to utilize additional frequencies. Food metal detectors that are equipped with Multiscan technology enable operators to pick a set of up to five frequencies from 50 kHz to 1000 kHz. Running five frequencies helps to get the machine close to ideal for any type of metal you might encounter, optimizing sensitivity.

With Multiscan technology, contaminants can be detected at any orientation even in salty or moist products that exhibit difficult product effect. With the ability to employ five flexible frequencies at once, the probability of detection increases dramatically and escapes disappear…no matter which way you look at it.

READER QUESTION

“Based on practical experience with different types of contamination, the orientation of the contaminants significantly impacts detection level. When the contaminant was placed flat on the product, the detection level was minimal. However, when it was positioned vertically, the detection level was at its highest. Giving this would it possible to use two metal detectors with detection coils in different orientation-one vertical and one horizontal to ensure complete detection?” – Rafid

ANSWER:

Based on practical experience, it is indeed possible to enhance detection by using two metal detectors with coils oriented differently – one vertical and one horizontal. This approach can significantly improve the detection of contaminants with the difficult orientation effect you have noted. Make sure your vendor provides free product testing to help ensure the effectiveness of detection systems for your specific requirements.

*This article was originally published May 27, 2020, under the byline Alexander Kinne but has been updated with the Reader Question, which was answered by Kimberly Durkot.

Very interesting and useful information. I hadn’t even thought about the importance of orientation for a food metal detector. Thanks for the article, it was helpful.

Based on practical experience with different types of contamination, the orientation of the contaminants significantly impacts detection level.

When the contaminant was placed flat on the product, the detection level was minimal.

However, when it was positioned vertically, the detection level was at its highest.

Giving this would it possible to use two metal detectors with detection coils in different orientation-one vertical and one horizontal to ensure complete detection.

Thank you for your question, Rafid. Please refresh your screen and read the end of the article for the answer. We would love to discuss your specific application and explore an effective solution. Additionally, we offer free product testing in our lab to help ensure the effectiveness of our detection systems for your specific requirements. Please feel free to reach out to us directly to discuss this in greater detail: https://www.thermofisher.com/us/en/home/global/forms/industrial/checkweighing-metal-detection-xray-systems-information-request.html?icid=CAD_blog_food_2025May