This piece was contributed by Kris Wronski, Cell Culture Application Scientist, Thermo Fisher Scientific. Download the full article here.

I will always cherish my time with the molecular haematopoiesis and epigenetics group at Leeds University, dedicated to advancing blood cancer research. Tackling the challenging project of developing a new technology to identify DNase I accessible regions in the eukaryotic genome was both demanding and rewarding. The core of my assay involved establishing primary macrophages and fibroblasts—no easy feat—and navigating a complex series of steps, including qPCR checkpoints with known active and inactive genomic regions.

The sensitivity of epigenetic assays is incredibly high, and any variables affecting your primary cells during incubation can significantly impact reproducibility. Our research group was extensive, resulting in high demand for CO2 incubator space. Consequently, my cell cultures might occupy the top shelf one week and the bottom shelf the next. At the time, I did not give this much consideration, attributing my failed experiments to factors such as media quality, reagents, complex protocols, or even my own pipetting accuracy. I never imagined that something as seemingly mundane as the design of a CO2 incubator could influence my experimental outcomes.

I hope the lessons I learned will encourage you to consider all experimental variables, no matter how minor they seem, and ultimately boost your success in cell culture experiments.

Cell culture is evolving fast

We’re shifting from traditional established cell lines to more sensitive options like stem cells, primary cells, and 3D cultures. The reasons are very clear, these advanced cell types better mimic the in vivo environment, providing clearer insights into complex biological questions as well as serving as potential therapeutics (2). Cells constantly interact with their surroundings, adjusting processes like transcription, translation, and cell division. Understanding how external cues influence cell behaviour is crucial.

Factors that affect cell growth include temperature, gas composition and relative humidity. For proper cell growth, these parameters should be optimal, stable and uniform throughout the incubator chamber.

To support these delicate cells and achieve accurate, in vivo-like responses, modern CO2 incubator must sustain truly uniform culturing conditions. But what does ‘uniformity’ really mean in the context of CO2 incubators? Let’s dive in. Understanding every aspect of incubator chamber design is crucial, as these elements collectively hold the key to successful cell culture and experimental reproducibility.

What does ‘Uniformity’ really mean?

For anyone culturing cells in multiple flasks simultaneously, eliminating environmental variables is crucial for obtaining clear and interpretable results. The primary factor that varies with incubator design is the uniformity of conditions throughout the entire chamber. What do we mean by uniformity? It’s the consistency of conditions from top to bottom and side to side within the incubator. Without good uniformity, cells in different areas experience varying conditions, leading to differences in protein expression, metabolism, and growth.

Have you ever considered the physics behind your cell culture environment? The incubator chamber must maintain challenging conditions, such as a 37 °C temperature, 5 % CO2 concentration, and high humidity levels (usually above 90 %). Additionally, some experiments require lower oxygen levels to create hypoxic conditions. All of this ensures that primary cells can best preserve their tissue-specific functionalities. For instance, heat naturally rises, creating temperature gradients from the top shelf to the bottom shelf. Higher concentration of CO2 molecules, being heavier than air, tends to sink, while nitrogen gas used to reduce oxygen concentration is lighter and rises. Understanding this, it’s clear that active air circulation is essential to maintain uniform conditions throughout the incubator chamber. This ensures that cells on different shelves experience the same environment (4,5).

Gentle air circulation ensures uniform growth conditions.

A circulating fan in the incubation chamber can provide uniform conditions and faster recovery speeds. While some myths suggest that fans are detrimental in CO2 incubators, this isn’t true for models with appropriately designed in-chamber circulating fans. Only well-engineered fan systems can achieve the highest uniformity and quickest recovery times for all parameters (3).

Modern, well-designed fans should effectively circulate air throughout the incubator chamber, creating a gentle airflow that prevents cultures from drying out and eliminates concerns about vibration (1,3).

Culturing primary cells in a fanless incubator can be costly.

Without circulating fan, conditions in the incubator chamber will stratify, creating different microenvironments in different areas. Fanless incubators rely on gravity convection or slow-moving thermal currents for humidity transport and gas exchange. This outdated design results in slower recovery rates, meaning that frequent door openings can prevent your cultures from experiencing the consistent conditions they need. With well-established mutant cell lines, inconsistencies in experimental results may be less pronounced. However, as the use of challenging primary cells and stem cells grows, along with the adoption of live imaging systems and intricate experimental protocols, the limitations of fanless incubators become glaringly apparent (6). These limitations can lead to significant inconsistencies, resulting in loss of expensive resources, your precious time and compromising the integrity of your research. This issue becomes particularly critical in incubators with variable oxygen control, as oxygen concentration affects nearly every cellular process (5).

An incubator with a circulating fan can be a game-changer

To elevate experimental success and reproducibility, an incubator with a circulating fan can be transformative. I only wish I had this insight and understanding during my cell culturing days in the cancer research lab.

Thermo Scientific CO2 incubators have earned their long-standing reputation for advanced active airflow technologies. Their precisely engineered fan-assisted airflow systems ensure efficient circulation of critical temperature, gas, and humidity conditions, safeguarding the integrity of your cells and enhancing the reliability of your results.

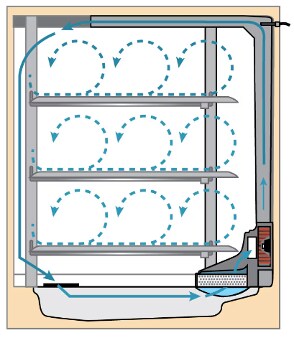

This critical advantage is why even well-established models like Thermo Scientific™ BB 15 CO2 incubator (Figure 1) and Thermo Scientific™ Heracell™ i CO2 incubators (Figure 2) remain among the most trusted and reliable on the market. These incubators are a testament to the fact that sustaining healthy cells and generating trustworthy data are paramount for scientists worldwide. Thermo Scientific is constantly evolving and innovating to meet the needs of their customers. Thermo Scientific Vios CO2 Incubators (Figure 3), featuring THRIVE active airflow technology, exemplify this commitment by offering even faster recovery and unparalleled uniformity for consistently reliable results (Watch THRIVE active airflow demo video).

Figure 1. The illustration of Thermo Scientific™ BB 15 CO2 incubator, internal chamber and external housing. The BB 15 incubator is available with a solid copper interior. The chamber, the shelving system, the fan and even the fan housing are made of solid copper.

Figure 2. The illustration of Thermo Scientific™ Heracell™ i CO2 incubator. The fan-assisted chamber design ensures homogeneous conditions throughout the entire chamber, so that all cells experience the same temperature, gas exchange and humidity, regardless of their location in the growth chamber.

Figure 3. The illustration of Thermo Scientific Heracell VIOS CO2 Incubator with internal 100% copper chamber (optional). And illustration of incorporated THRIVE active airflow technology, providing faster recovery and uniformity for consistent results.

Summary

Without good uniformity, cells in different areas of the incubator will experience different conditions, increasing variability in your results. Some cells may never encounter the proper conditions at all. Active air circulation is the key to maintaining uniformity. Incorporating a circulating fan in your CO2 incubator ensures optimal conditions for your primary cell cultures, leading to more reliable and reproducible experimental results.

Thermo Scientific fan-assisted incubator designs ensure homogeneous conditions throughout the entire chamber, so that all cells experience the same temperature, gas exchange and humidity, regardless of their location in the growth chamber. These standardized conditions form the basis of good, controlled science and meaningful, reproducible results.

Don’t let outdated myths hold you back—embrace the benefits of modern fan technology for superior cell culture performance.

References:

- Esser, P and Weitzmann, L. Evaporation From Cell Culture Plates. Thermo Scientific 2011, TILSPNUNCBU02 0111.

- M. Bates, “Designing Incubators for Cell Therapy Manufacturing,” Pharmaceutical Technology 45 (8) 2021.

- Thermo Scientific Smart Note (2022): Why is a circulating fan essential to superior growth conditions in a CO₂ cell culture incubator?

- Thermo Scientific Smart Note (2022): Which incubation parameters are most important for proper cell growth and expression?

- Thermo Scientific Poster: Redefining “Biologically Relevant” in Relation to Oxygen Availability. (Visit: assets.thermofisher.com/TFS-Assets/LPD/posters/Hypoxia-Poster-CO2-Incubator.pdf)

- Thermo Scientific Smart Note (2020): What features are essential when considering a CO2 incubator for housing an in-chamber live cell imaging system?

| Save and download this article. http://thermofisher.com/TFS-Assets/LPD/Reference-Materials/cell-culture-uniformity-active-airflow.pdf |

| For Laboratory Use. It is the customer’s responsibility to ensure that the performance of the product is suitable for customers’ specific use or application. |

Leave a Reply