Editor’s Note: This is the second article in a 3-part series on How to Relate Test Results of a Torque Rheometer to Problems in Elastomer Processing

Rubber compounds containing all curing agents such as sulphur and accelerators vulcanize, of course, at a higher temperature. Vulcanization hardens the material and gives it more strength, elasticity and durability. This vulcanization process can be monitored at best at its onset. It is of interest for the rubber technologist to determine how long a particular compound can still be mixed, extruded or injection-moulded at a given temperature and how fast viscosity will change once vulcanization has started.

Rubber compounds containing all curing agents such as sulphur and accelerators vulcanize, of course, at a higher temperature. Vulcanization hardens the material and gives it more strength, elasticity and durability. This vulcanization process can be monitored at best at its onset. It is of interest for the rubber technologist to determine how long a particular compound can still be mixed, extruded or injection-moulded at a given temperature and how fast viscosity will change once vulcanization has started.

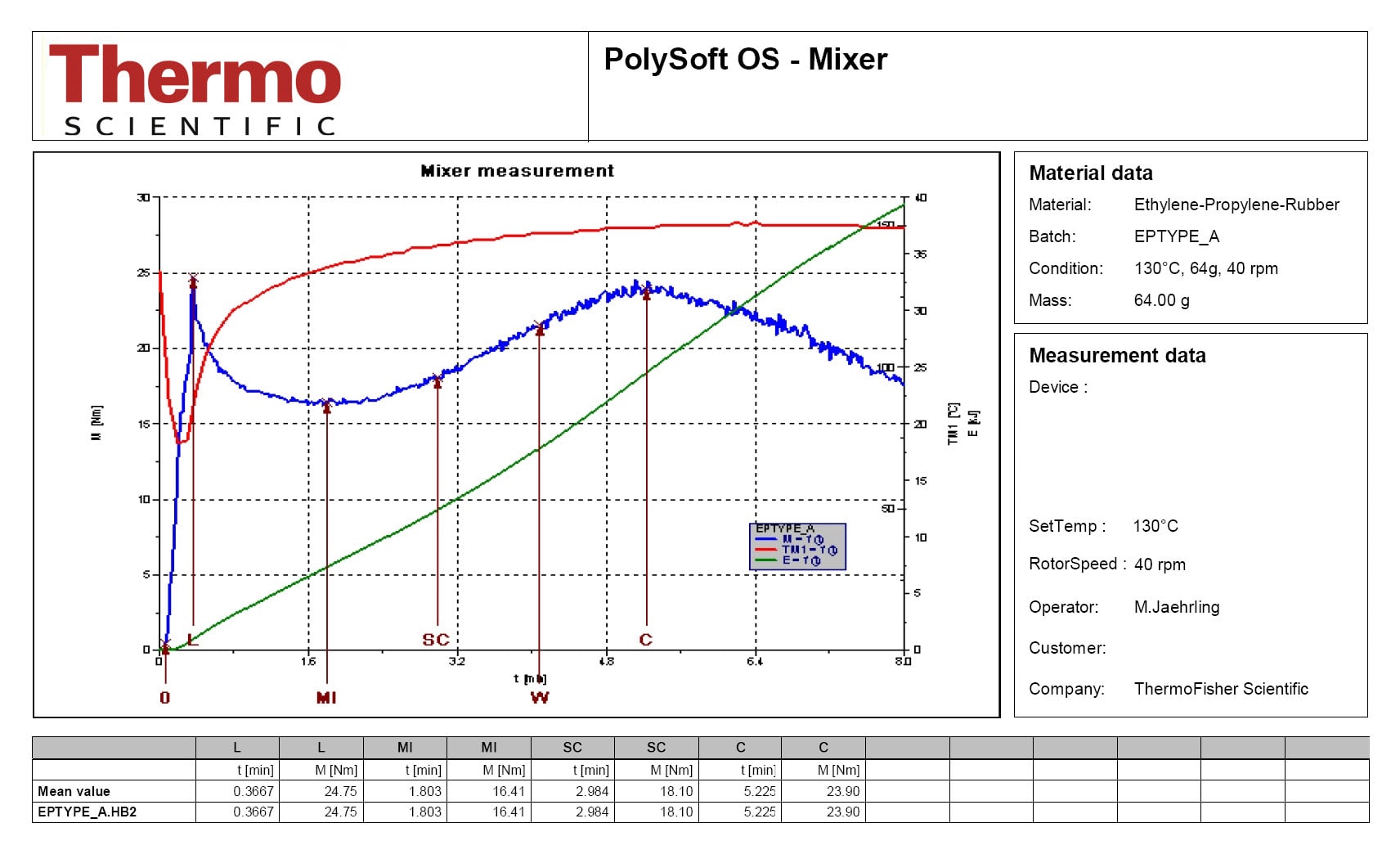

We used a torque rheometer to test materials used in elastomer processing. This chart shows the original torque and stock temperature of a flow curing test of an ethylene-propylene rubber compound (EPTYPE_A) and the corresponding evaluation of the test data.

This graph illustrates:

- The Loading Peak (L)

- The minimum torque (M), i.e. the viscosity before the onset of cure

- The time required (scorch time) to reach a torque limit expressed as a variable percentage higher than the minimum viscosity, e.g. 15 %

- The time required to reach a second torque limit of well advanced “cure“ which may be perhaps 50 % higher than the minimum viscosity

- The ratio of these two torque limits defines the rate of vulcanization

A second ethylene-propylene rubber, yielding the same MOONEY viscosity (EPTYPE_B), was tested under the same conditions. The manufacturer of these two EP compounds assumed that both would have the same flow properties. However, when the elastomers were processed, differences contradicting the results of the MOONEY test were observed.

The comparison of the two compounds is portrayed here:

During the mixer test, the sample is sheared as it was in the production process. Because of this, the mixer test shows differences which couldn’t be seen with the MOONEY test. The compound EPTYPE_A shows a lower torque level than sample EPTYPE_B. It therefore flows more easily, thus resulting in better processing properties. Additionally the time for cure is shorter.

For more details, read How to Relate Test Results of a Torque Rheometer to Problems in Elastomer Processing.

Leave a Reply