In September this year, the Bank of England issued the “New Fiver,” a £5 note made of polymer. According to the bank’s web site, more plastic money is on the way; the £10 note will be issued in summer 2017 and the £20 note by 2020.

In September this year, the Bank of England issued the “New Fiver,” a £5 note made of polymer. According to the bank’s web site, more plastic money is on the way; the £10 note will be issued in summer 2017 and the £20 note by 2020.

The bank boasts that polymer banknotes are more sanitary, last much longer, and are much more difficult to counterfeit than paper money, and they’re not the first to have thought so. Polymer banknotes have been in use in Australia for decades and many other countries, including New Zealand, Canada, and Romania, rely on polymers for clean, recyclable, and easily verifiable currency. And apparently there is one more advantage to polymer banknotes if you’re a vinyl record enthusiast—Plastics News reports that someone discovered that the crisp, clean edges of the New Fiver can be used in place of a needle to play a vinyl record.

Many banknotes are made from a polymer such as biaxially oriented polypropylene (BOPP). The Bank of Canada makes its banknotes from polyethylene terephthalate (PET). PET is a strong, lightweight, transparent plastic commonly used to make drink bottles, cosmetic and food-grade packaging, and as a basic material for blood vessel implants.

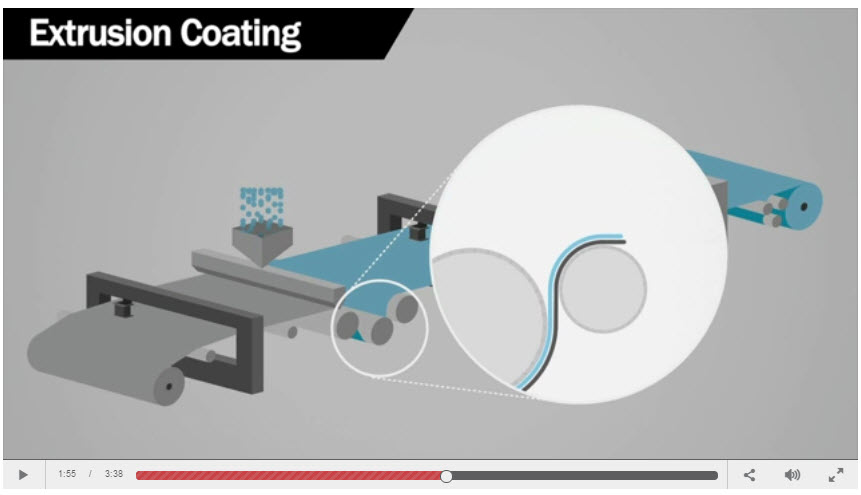

The process of fabricating polymer materials into currency starts with small polymer pellets that are melted and then stretched into a 5-story tall thin plastic “bubble.” At the bottom of the bubble, the polymer is cooled and gathered into rolls, where an infrared gauge checks that the polymer film has the correct thickness. The polymer sheets are wrapped into rolls, and then printed with the banknote design as well as security features that help to prevent counterfeiting. Watch this video describing the polymer banknote manufacturing process.

Thickness sensors for web gauging measure based on the absorption of light by the materials being scanned. Each material exhibits a unique light absorption characteristic and emits a signature waveform (spectra) as light passes through it. As material thicknesses change, the spectra will change throughout the infrared wavelength spectrum.

Some sensors are designed to inspect the entire infrared spectrum to accurately measure thicknesses of both single layer and multilayer products. This technique enables the sensor to discriminate between different components even if they exhibit very similar IR absorption characteristics.

Watch this video to see a complete measurement and control system for plastics films and packaging.

Scroll down on page to watch the video:

Note Canadian banknotes are not made from PET. They are made from the same BOPP as are all polymer banknotes

Gary power