Smelting and its byproducts

Smelting, the process of extracting base metals from their natural states (ores), has been used since the bronze age to create precious and useful metals. Ore is decomposed in smelting with heat and a chemical reducing agent such as calcium, driving off other elements as gases or slag and leaving the metal base behind.

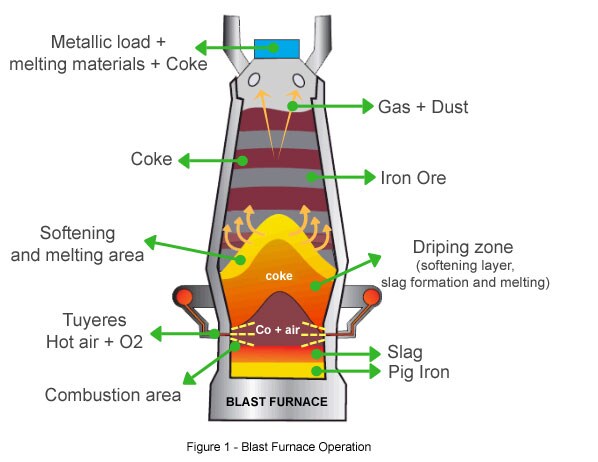

Blast furnace operation

What is slag?

In modern steel making, slags originate in a blast furnace from impurities in the iron ores (known as the gangue), the flux and coke ash. This is a complex mixture of silica, alumina, sulfides and oxides of calcium and magnesium, as well as smaller amounts of manganese and iron oxides. In an electric arc furnace, the slag formation process can be controlled by addition of oxygen, carbon and slag formers such as lime (CaO) and magnesia (MgO) to the melt.

Uses of slag

This by-product of the blast furnace has many uses, including Portland cement, masonry, ready-mix concrete, precast concrete, hot mix asphalt aggregate, rural pavements, septic drain fields, pipe backfill, shoreline riprap, floor leveling compounds and high temperature resistant building products. Slag from electric arc furnaces are blended with materials such as granulated slag, fly ash and lime to form pavement material, skid resistant asphalt aggregate and flowable fill construction materials.

Due to the intrinsic value of slag, it is important that analytical tools are available to identify and quantify the chemical composition in slag. X-ray fluorescence spectrometry (XRF) provides a rapid, reliable and repeatable solution to measure slag.

What is X-ray fluorescence spectrometry

An elemental spectroscopy, XRF uses an excitation source to energize samples. As electrons are ejected from the atoms within the sample, the replacement process whereby the atom regains its stability creates a characteristic X-ray energy. Since each element contains a unique atomic structure, detecting a spectrum of energy values determines the elemental composition of the sample. This process is quick, requires minimal sample prep (generally pelletizing), and is basically foolproof.

Recent developments in X-ray detection enable the XRF spectrometer to achieve remarkable sensitivity and repeatability. New X-ray detector technology provides solid-state detection without the need for external cooling. A silicon drift detector (SDD) coupled to a fast CMOS ASIC preamplifier provides high count rates with excellent resolutions. A large detector area ensures solid angle geometry that maximizes the capture of X-rays produced by the sample.

As an analytical instrument, an Energy-Dispersive XRF (EDXRF) spectrometer features a durable mechanical design, compact footprint and minimal site requirements permitting placement in rough environments such as near the furnace. Routine analysis can be performed by unskilled personnel, and the hardware is controlled solely by software to assure data integrity and reduce operational complications due to mechanical buttons or controls.

XRF of slag

Scientists at Thermo Fisher Scientific analyzed metallurgical slag samples with the Thermo Scientific™ ARL™ QUANT’X EDXRF Spectrometer. Applications of XRF in industrial process control are calibrated using empirical calibrations on the basis of primary or secondary standards. The results were obtained using a multi-variable regression curve based on 20 secondary slag standards. All calibration functions, curve display and fit evaluations are included in the standard software package supplied with the ARL QUANT’X Spectrometer.

To evaluate the spectrometer’s repeatability, tests were performed to show the typical precision achieved by the ARL QUANT’X Spectrometer for a 3-minute total counting time. The statistical summary of ten measurements of three slag samples were presented.

To learn more about how an EDXRF spectrometer can be used to analyze various components in slag, read “Analysis of metallurgical slags with ARL QUANT’X EDXRF Spectrometer.”

there should be uses of such parts of a blast furnance

I agree, so disappointing that they do not give further information. If you have found a site with additional information, please reply. Many thanks.