Monitoring the presence of wear metals in lubricants, oils and other machine fluids is a preventive measure to identify potential problems with an engine. Early detection of wear metals in lubricants and greases avoids expensive damage – and downtime – to high value engines, gears, generators, turbines and other equipment. Energy-dispersive X-ray fluorescence (EDXRF) spectrometers are an ideal instrument for analyzing wear metals in lubricants, as determined by a recent study summarized here.

Monitoring the presence of wear metals in lubricants, oils and other machine fluids is a preventive measure to identify potential problems with an engine. Early detection of wear metals in lubricants and greases avoids expensive damage – and downtime – to high value engines, gears, generators, turbines and other equipment. Energy-dispersive X-ray fluorescence (EDXRF) spectrometers are an ideal instrument for analyzing wear metals in lubricants, as determined by a recent study summarized here.

Sample preparation

The oil sample is measured as such by transferring 3 grams of product into a sample cup of 32 mm outer diameter, sealed with a 4 micron polypropylene film.

Excitation conditions

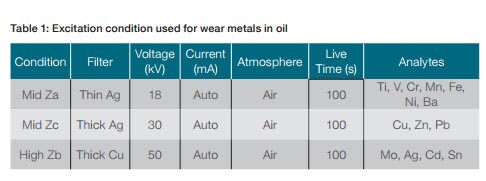

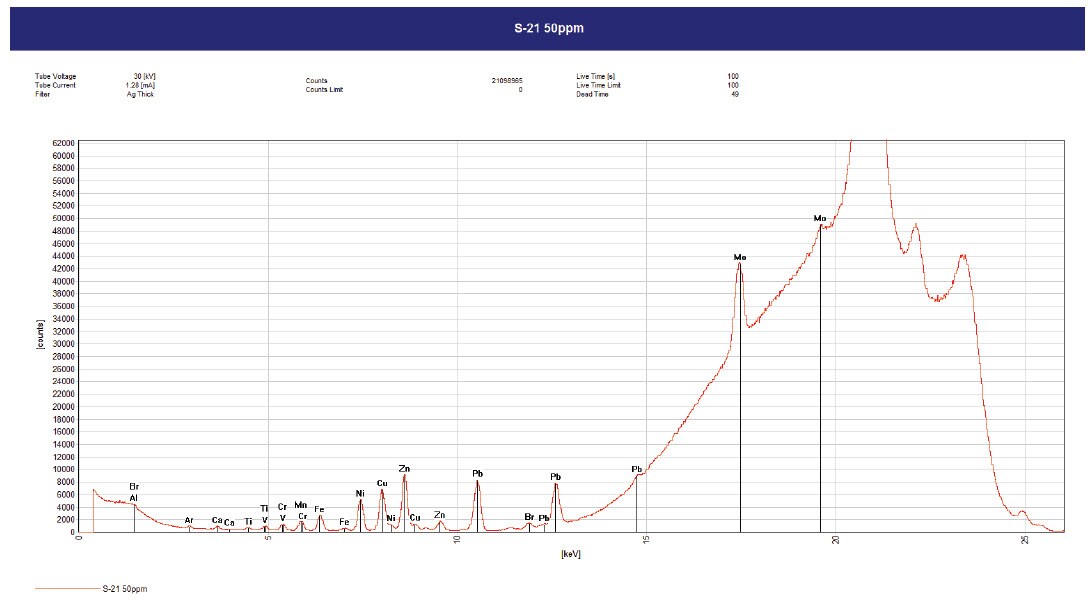

Table 1 shows the excitation condition used to perform the analysis. Three different filter conditions have been used to cover 14 elements. A live time of 100 s is used for every condition. Figure 1 shows a typical spectrum obtained using condition Mid Zc of a sample containing several elements of interest at 50 ppm. Condition Mid Zc is optimized to excite copper, zinc and lead but also excites many of the other wear metals typically monitored.

Figure 1: Typical spectrum for wear elements at 50 ppm in oil using condition Mid Zc (30 kV, thick Ag filter) in an air atmosphere

Calibration

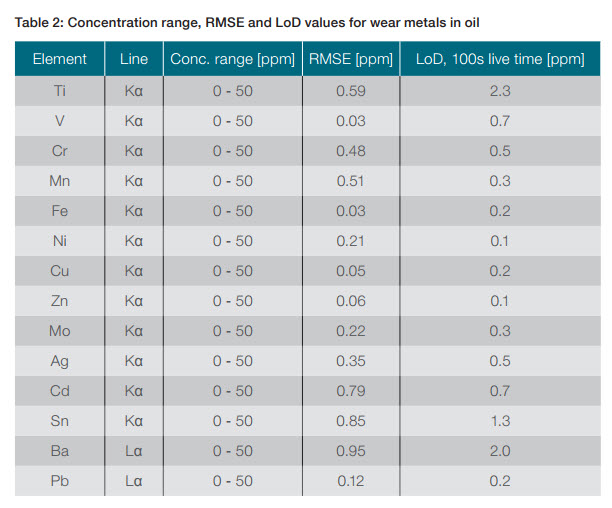

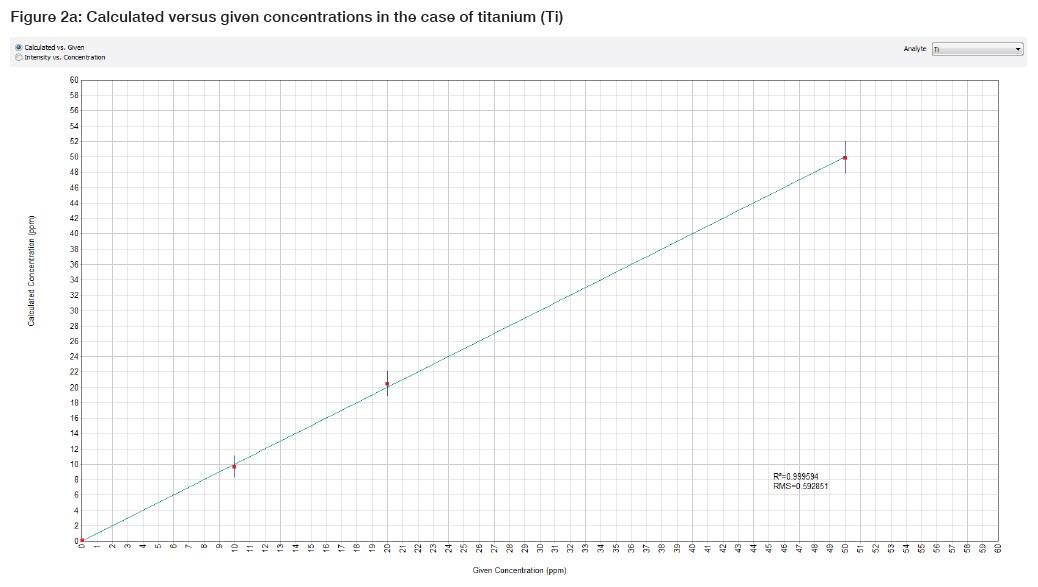

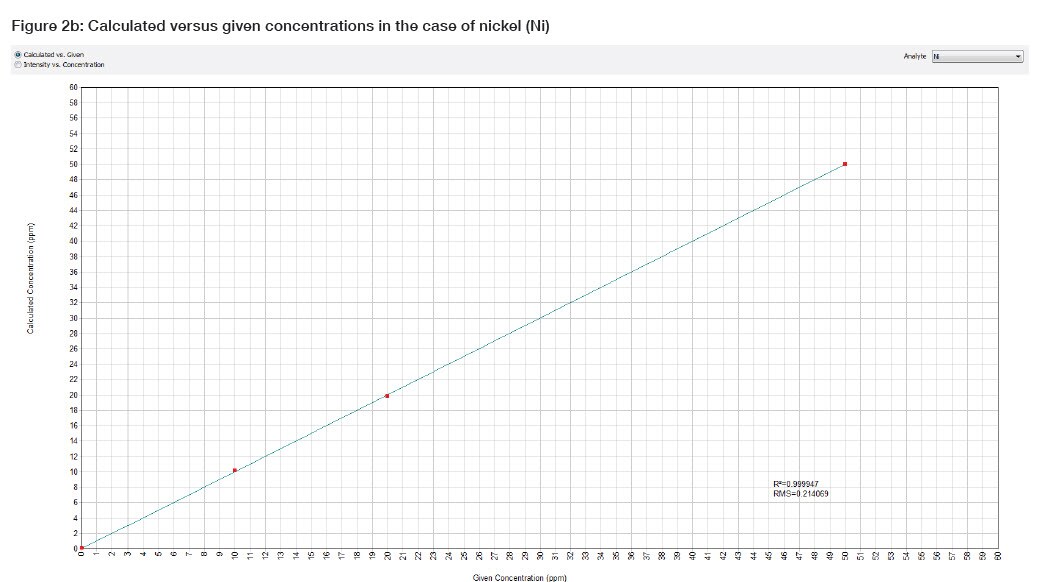

Linear calibration curves relating net intensities to concentrations are set up with standards prepared using a Conostan S21 50 ppm standard, diluted using 75 cSt blank oil (also from Conostan). Three concentration levels; 10 ppm, 20 ppm, 50 ppm and a blank were prepared to set up the curves and to determine the detection limits. Figures 2a and 2b show the calibration curves obtained for titanium (Ti) and nickel (Ni). Root mean square errors (RMSE) of 0.6 ppm (Ti) and 0.2 ppm (Ni) are obtained. Table 2 also shows the RMSE values obtained for the other elements of interest.

Figure 2a: Calculated versus given concentrations in the case of titanium (Ti)

Figure 2b: Calculated versus given concentrations in the case of nickel (Ni)

Limit of detection

To determine the limit of detection (LoD), 10 XRF cups were filed with 3 grams of the blank oil and analyzed subsequently. The LoD is calculated to be three times the standard deviation of the concentrations derived for each element.

Conclusion

EDXRF provides fast, accurate and repeatable monitoring of wear metals in lubricants, oils and machine fluids. Analysis of such samples can be done under ambient air which is convenient, shortens analysis time and offers savings on costly helium gas consumption.

Read the complete application note, Analysis of wear metals in oil under ambient air using the ARL QUANT’X EDXRF.

Leave a Reply