Versatile titanium (Ti) can be found everywhere, from tennis rackets to jet engines.

Other uses:

- Due to excellent resistance to sea water, titanium is used to make propeller shafts and rigging and in the heat exchangers of desalination plants and in heater-chillers for salt water aquariums.

- Because it is considered to be physiologically inert, titanium is used in joint replacement implants such as hip ball and sockets and to make medical equipment and in pipe/tank lining in food processing. Titanium is also used for surgical instruments.

- Titanium alloys make highly durable and long lasting eye glass frames. Both traditional alloys and shape memory alloys find use in this application.

- Many backpackers use titanium equipment, including cookware, eating utensils, lanterns and tent stakes because titanium products can be significantly lighter without compromising strength.

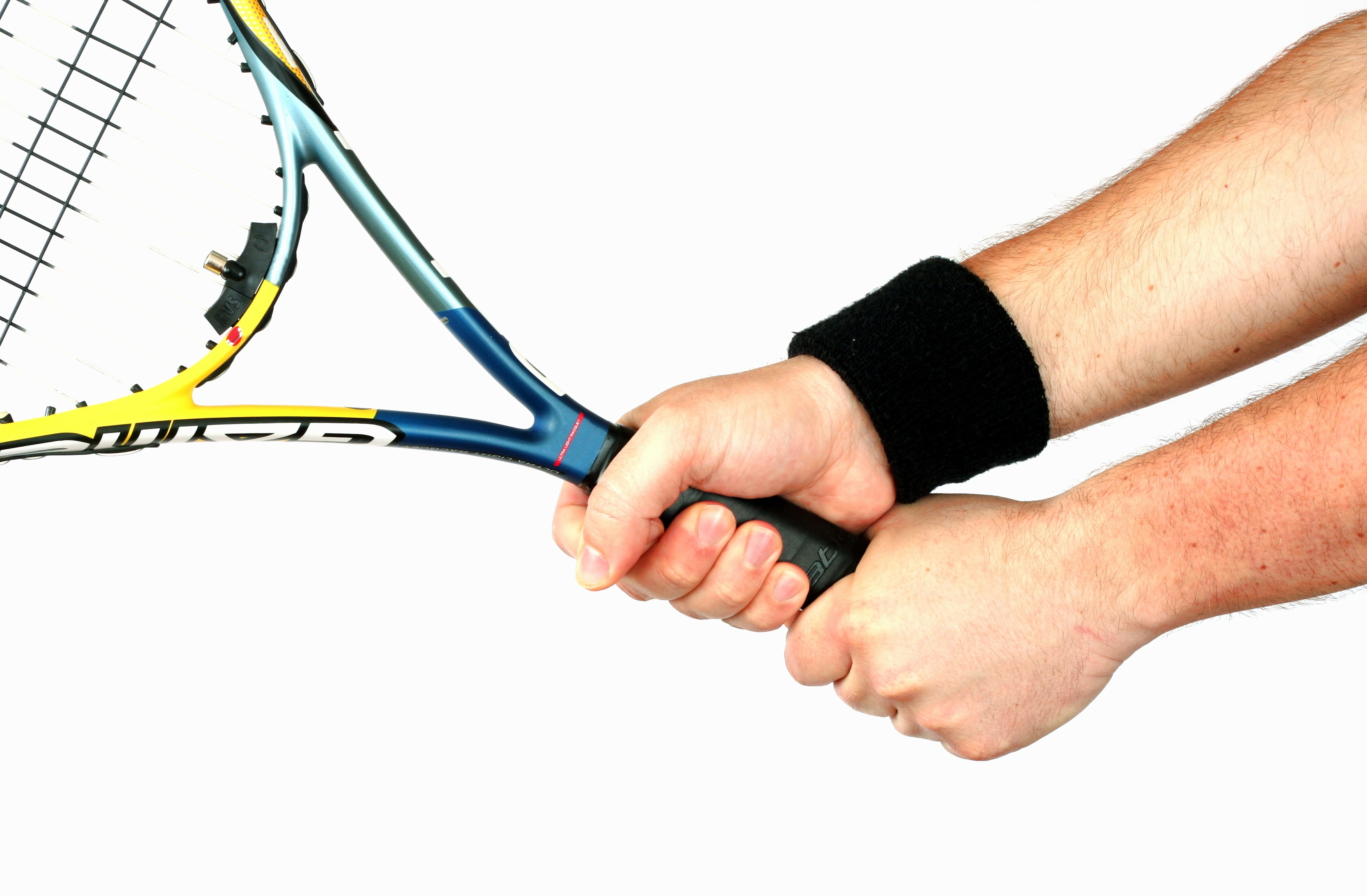

- Titanium is popular in consumer products such as tennis rackets, golf clubs, bicycles, laboratory equipment and laptop computers.

Learn more about the many properties and applications of titanium in the International Titanium Association’s Ti Facts.

The market for titanium is sizeable. According to the U.S. Geological Survey, the value of titanium mineral concentrates consumed in the United States in 2013 was about $1,140 million. About 95% of mined and synthetic titanium mineral concentrates was used to make titanium dioxide (TiO2) a pigment used to impart whiteness to paper and inks. The remaining 5% was used in welding-rod coatings and for manufacturing carbides, chemicals, and metal.

Of the titanium used to make metal, titanium is added in steel alloys to reduce grain size and as a deoxidizer, and in stainless steel to reduce carbon content. Titanium is often alloyed with aluminum (to refine grain size), vanadium, copper (to harden), iron, manganese, molybdenum, and other metals.

The quality and composition of all of the materials that go into making these metal blends must be verified. For example, if the titanium used in the manufacture of propeller shafts or other parts designed for underwater use is not alloyed with the right metal for the application, the parts won’t have the needed corrosion resistance. Similarly, titanium must be alloyed with precise amounts of platinum, palladium, or ruthenium to make pipes that can withstand harsh chemical processing environments.

With both examples, it’s clear that out-of-specification metal alloys can lead to expensive and potentially dangerous part failures. Portable XRF analyzers are indispensible tools for performing material verification for quality control of incoming raw materials, work in progress, and final quality assurance of finished parts, distinguishing alloy grades that are nearly identical in composition to one another in seconds.

Yes, Titanium Is The Best Metal

We Deep Steel Alloys Are Stockist Of Titanium Sheet And Plate And Other Raw Materials Like Pipe, Plate, Flange, Fittings, Rod, Coil, Bar, Round Bar, Wire, Electrodes