The first post in this series, Laboratory-based XRF vs. Handheld XRF: What’s the Difference? explained the difference between handheld and lab-based XRF analysis. The two primary types of lab-based XRF systems are Energy Dispersive X-ray Fluorescence (EDXRF) and Wavelength Dispersive X-ray Fluorescence (WDXRF). The second post in this series reviewed EDXRF. In this final installment, we’ll look at WDXRF.

How It Works

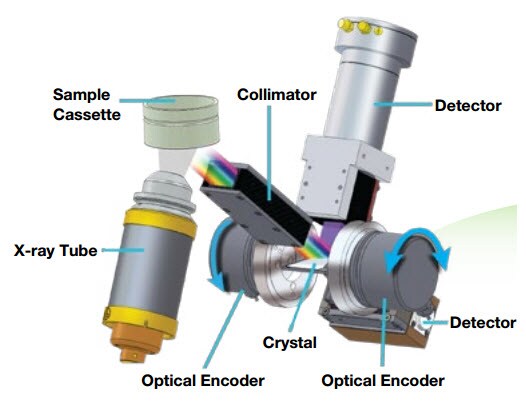

WDXRF uses crystals to disperse the fluorescence spectrum into individual wavelengths of each element, providing high resolution and low background spectra for accurate determination of elemental concentrations. The types of crystals used in WDXRF include minerals, metallic, organic and synthetic multi-layers. Synthetic thin film multilayer crystals are increasing in popularity because they offer higher sensitivity and resolution for enhanced light element analysis. Some traditional crystals are sensitive to instrument temperature changes and x-ray exposure and will degrade over time.

WDXRF systems are based on Bragg’s law, which states that crystals will reflect x-rays of specific wavelengths and incident angles when the wavelengths of the scattered x-rays interfere constructively. While the sample position is fixed, the angles of the crystal and detector can be changed in compliance with Bragg’s law so that a particular wavelength can be measured. Only x-rays that satisfy Bragg’s law are reflected.

Collimators further improve resolution by providing different angular divergences to restrict unwanted secondary x-rays from reaching the detector. Larger collimators can be used when high intensity is favored over resolution.

Detectors

Two types of detectors can be used in WDXRF instruments. Sealed or flow gas detectors are best for measuring lower energies (light elements, below iron [Fe]), while scintillation detectors are better for measuring higher energies. Both have poor resolution, which is compensated for by the crystals. WDXRF analysis can be performed either sequentially using goniometers or simultaneously using monochromators.

Goniometers

Detectors can be mounted on a goniometer and moved through a range of angles to measure the intensities of different wavelengths in sequential fashion. This system offers flexibility and optimum performance across the periodic table. However, the sequential nature of WDXRF instruments and the need to readjust the geometry between measurements make them operate slowly.

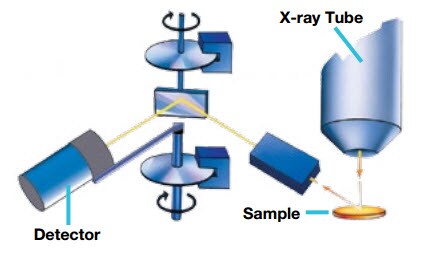

Monochromators

When monochromators are used, the crystal and detector combination is in a fixed geometry. Each monochromator measures a single element but they all work simultaneously. This set-up offers speed and precision for a given set of elements.

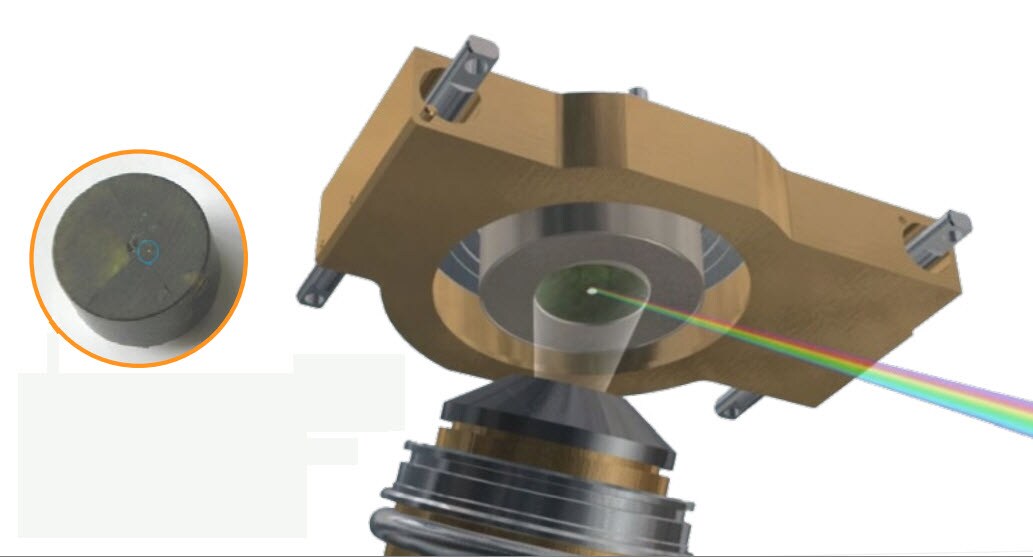

Small Spot Analysis

Some instruments feature small masks that restrict the analyzed area on the sample. Combined with appropriate sample movement, this allows the measurement of an individual spot of the sample. When samples present a defect, the ability to analyze a small area in isolation can help determine the source of the defect. XRF instruments with a spotting capability are used for this purpose in various industries like glass and metal production.

Elemental Mapping

XRF Mapping is a great tool to measure the homogeneity of a sample in a sub-millimeter size range. This can help validate sample preparation or indicate problems in a process. Geologist’s use XRF elemental mapping to select or screen samples for more in-depth analysis with a scanning electron microscope (SEM), which requires highly controlled sample preparation and provides information in the sub-micrometer size range.

Want to learn more about lab-based XRF? Download our free eBook: XRF in the Lab for the Non-Scientist.

Leave a Reply