Where can we find some additional critical mineral resources? That’s what the USGS is asking and is now carrying out new mapping programs to find out. The USGS Earth Mapping Resource Initiative is a program aimed at improving “knowledge of the geologic framework in the United States and to identify areas that may have the potential to contain undiscovered critical mineral resources.” The organization published an article this week based on what they have learned in the year it has been active.

Where can we find some additional critical mineral resources? That’s what the USGS is asking and is now carrying out new mapping programs to find out. The USGS Earth Mapping Resource Initiative is a program aimed at improving “knowledge of the geologic framework in the United States and to identify areas that may have the potential to contain undiscovered critical mineral resources.” The organization published an article this week based on what they have learned in the year it has been active.

Some of the areas explored include:

- Illinois-Kentucky fluorspar mineral district. Fluorspar is mainly used in the manufacture of aluminum, gasoline, insulating foams, refrigerants, and uranium fuel. The fluorspar mineral summary reports that in recent years, several of the world’s leading mines have been operating at or near full capacity. Fluorspar is also used in cement production, in enamels, as a flux in steelmaking, in glass manufacture, in iron and steel casting, and in welding rod coatings. The minerals report also notes that “synthetic fluorspar may be produced from neutralization of waste in the enrichment of uranium, petroleum alkylation, and stainless steel pickling; however, undesirable impurities constrain use. Primary aluminum producers recycle HF and fluorides from smelting operations.”

- Additional mapped areas include South Carolina, the Mojave Desert of California and Nevada, and northern Arkansas for locations of rare earth elements. Rare earth elements (REEs) are critical to electronics, renewable energy, and defense applications. We’re previously written about REEs. Despite the name, these elements – defined as the 15 lanthanides plus scandium (Sc) and yttrium (Y) – are not as rare as one might think. Although originally thought to be rare, many of the minerals are actually common in the Earth’s crust. However, due to the difficulties in extracting the metal from the ore, rare is a fitting term. These elements rarely exist in pure form; they are usually found within other minerals, making them costly to mine.

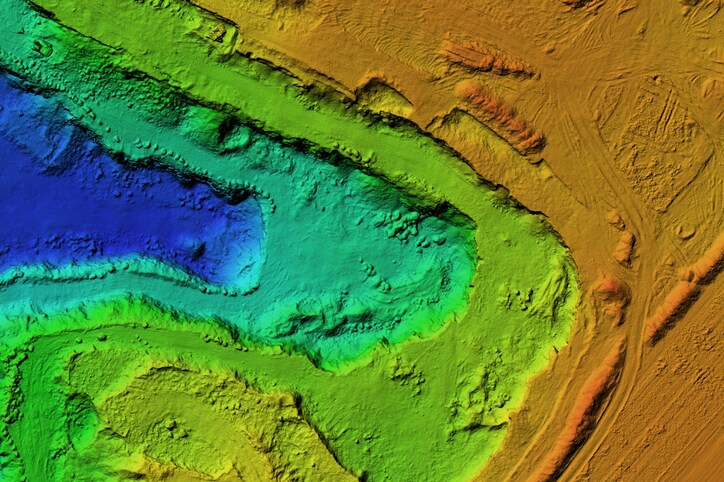

The areas have been mapped by small aircraft utilizing the latest scanning technology while zig-zagging low in the sky over farms and country roads. But when it comes time to explore on earth, it makes sense to utilize portable X-ray Fluorescence (XRF) analyzers.

Miners seek solutions for rapid geochemical analysis that will enable them to increase discovery success rates, identify drill targets quickly, make on-site decisions about whether to stop or continue drilling, and decide where to focus on the grid. Miners must also get an accurate report to the capital markets as fast as possible.

As we noted, REEs rarely exist in pure form; they are usually concentrated in more than one mineral, and each mineral requires a different costly extraction technology and mineral processing. Geochemical exploration is the main method of REE exploration. Depending on the REE project type, XRF analyzers can provide real-time, on-site assays of REEs and other elements in any type of geological samples. They are indispensable tools for the analysis of the light series of REEs (LREEs), including lanthanum (La), cerium (Ce), praseodymium (Pr), and neodymium (Nd). Other elements associated with REE-bearing minerals such as thorium (Th) and Yttriym (Y) can also be analyzed. By using the concentrations from these elements, especially Y, it is possible to infer concentrations of heavy REEs (HREEs) that are commonly associated with Y-containing host minerals.

Portable X-ray fluorescence (XRF) analyzers are making a critical difference in mining exploration and production. Designed for rugged field environments, they provide rapid, on-site qualitative screening directly in-situ or lab-quality quantitative analysis on prepared samples, bypassing the costly and time-consuming process of sending samples to off-site laboratories and waiting days, or even months, for critical data. With rapid sample analysis, you get real-time geochemical data to guide drilling decisions, enable high-productivity operations, and gain a competitive advantage.

And no small airplanes are needed.

Post Author: Marlene Gasdia-Cochrane.

Leave a Reply