Search Thermo Fisher Scientific

Thermo Scientific™

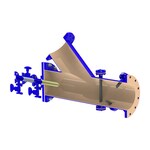

Pressure Pipe Sampler

Catalog number: 19515

Have Questions?

Thermo Scientific™

Pressure Pipe Sampler

Catalog number: 19515

Have Questions? The Thermo Scientific™ Pressure Pipe Sampler is a simple, low-cost solution for the continuous sampling of pressurized slurry streams for online analysis. With a choice of nozzles for efficient sample flow rate management with minimal risk of blockage, it incorporates three turbulence bars to deliver well-mixed samples for multi-stream analyzers such as the MSA-330 and GS Omni. It can also be used as a primary sampler for other incremental sampling solutions. Use the Pressure Pipe Sampler to access cost-efficient online measurement to improve the monitoring and control of mineral beneficiation plant and other slurry processes.

| Description | Pressure Pipe Sampler |

| Certifications/Compliance | Adelaide manufacturing site is quality assured to ISO 9001:2000; Metalwork manufactured to Australian standard AS4041-2016 (or equivalent) |

| Includes |

|

| Diameter | Available in 80 mm (4 in) NB to 900 mm (36 in) NB |

| Unit Size | Each |

Showing 1 of 1

| Catalog Number | Specifications | Unit Size | Description | Price (USD) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 19515 | Each | Pressure Pipe Sampler | Request A Quote | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The Pressure Pipe Sampler is a simple, practical continuous sampling solution for pumped slurry systems for process monitoring applications. Key features include:

- Wide range of pipe and nozzle sizes, for flexible configuration to handle most process flows.

- Table D, E and ANSI flanges available, for compatibility with a range of design standards.

- Replaceable polyurethane coated turbulence bars, for easy, low-cost maintenance.

- Rubber-lined with a durable finish, for longevity even with aggressive process streams.

- Optional continuous and backwash sample valves, for minimizing the risk of blockages.

Figures

Documents & Downloads

Certificates

Search by lot number or partial lot number

Frequently asked questions (FAQs)

Citations & References

Search citations by name, author, journal title or abstract text