Search Thermo Fisher Scientific

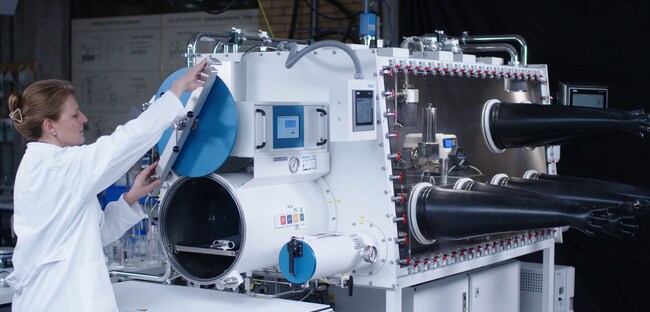

Energy 11 PROTECT Glovebox Solution

Energy 11 PROTECT Glovebox Solution

| Product Type | Glove Box |

| Amperage | 16 |

| Description | Energy 11 PROTECT Glovebox with intergated Energy 11 Twin-Screw Extruder |

| Dimensions (L x W x H) | 320 x 140 x 240 cm |

| For Use With (Application) | Battery materials |

| Includes |

|

| Voltage | 400 V |

| Unit Size | Each |

| Catalog Number | Specifications | Unit Size | Price (USD) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 553-0800 | Each | Request A Quote | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Due to its wide range of accessories, the Energy 11 PROTECT integrated glovebox solution allows users to develop and produce cathode and anode slurries as well as electrolytes for solid state batteries. Its high dispersive and distributive mixing capabilities also make possible the processing of dry electrodes under an argon atmosphere.

All extruder product contact parts can be disassembled completely and quickly for easy and thorough cleaning and to prevent cross contaminations. Rapid changes to experiment conditions are enabled by this feature as well.

Whatever your material requirements are, a range of feeding options for solid and liquid materials, all controlled by the extruder’s control panel, make sure that all ingredients go into the process precisely. Being a continuous process by design, the mixing done by the Energy 11 extruder eliminates batch to batch variations and always delivers a thoroughly homogenous final product.

APPLICATIONS

• All solid-state battery material mixing

• Handling of pure lithium anodes

• Separator film extrusion

• Lithium-ion electrode slurry mixing

• Solvent reduced mixing and dry cathode processing