Search Thermo Fisher Scientific

- Contáctenos

- Orden Rápida

-

¿No tiene una cuenta? Crear una cuenta

Search Thermo Fisher Scientific

| Aplicaciones | Vinyl Calender |

| Descripción | Vinyl Calendering |

| Unit Size | Each |

| Número de catálogo | Especificaciones | Formato | Descripción | Precio (CLP) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S-APP50-16 | Each | Vinyl Calendering | Solicite un presupuesto | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

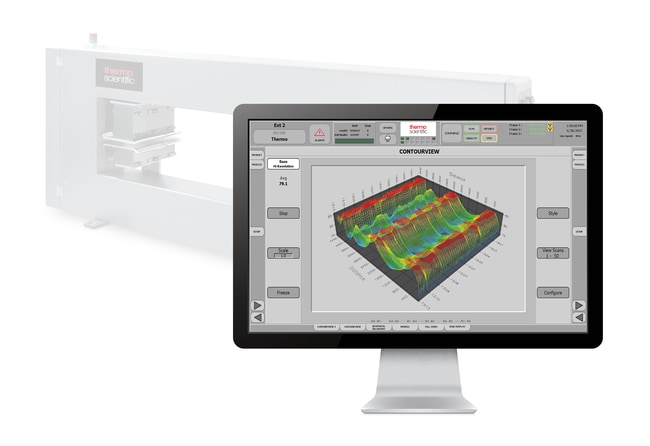

The 21PlusHD Measurement and Control System for Vinyl Calendering consists of a scanner, sensor and control system tailored to the application.

System components for vinyl calendering applications:

Thermo Scientific™ Mark III or L400 scanner, Thermo Scientific™ Beta Plus basis weight sensor, Thermo Scientific™ ShadowMaster direct thickness sensor or Thermo Scientific™ X-Ray Master weight and thickness sensor, and calender control with feed forward.

Operator Interface:

WonderWare HMI. Operator stations are PC-based and communicate with other system modules across an Ethernet LAN. Desktop interface and/or console configurations are available.

Communication Capabilities:

The 21PlusHD measurement and control system provides powerful communication capabilities with industry accepted OPC standards, allowing the sharing of product and process data with popular software packages for data acquisition, database building and quality analysis.

Instrument Performance Management

Thermo Scientific Instrument Performance Management (IPM) Software is included as part of a Product Support Agreement (PSA) and provides cloud-based 24/7 remote monitoring of the health, status and performance of gauging instruments. As part of our commitment to deliver proactive and predictive support services, IPM Software offers fast restoration of performance and minimizes downtime through automatic notifications for troubleshooting, advanced diagnostics to support root cause analysis and faster repair times.